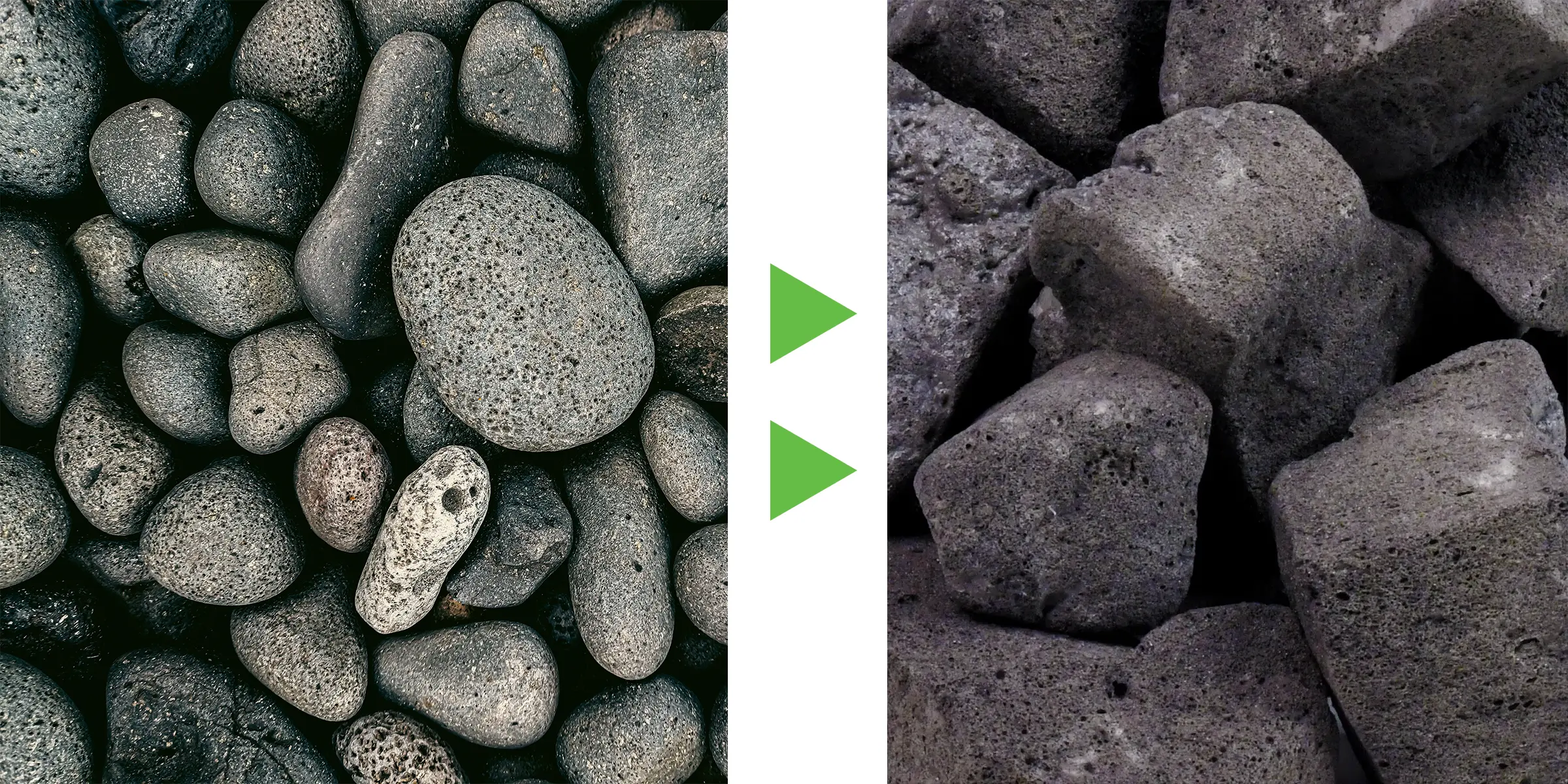

Replace river rock with Cell-Max™ Plus for consistent porosity and moisture retention.

Traditional river rock has long been used as a plenum and header base cover layer in biofilters and bioscrubbers. However, modern odor-control systems demand materials that provide consistent airflow distribution, reduced dead load, and long-term resistance to acidic environments.

This white paper presents the technical basis for using GES Biotek’s Cell-Max™ Plus as a superior alternative to river rock for plenum protection applications.

Crushing Load and Structural Performance

A critical design consideration for any plenum protection layer is its ability to withstand compressive loading from the overlying media bed under fully saturated operating conditions. Cell-Max™ Plus is a rigid, engineered inorganic substrate manufactured from recycled glass and designed for sustained structural stability.

Tested compressive strength (crushing load) for Cell-Max™ Plus is 13,000 lb/ft2 (622 kPa).

This value provides a substantial safety factor relative to the compressive stresses imposed by typical 3-to-5-foot-deep biofilter or bioscrubber media beds, even under conservative assumptions that include full saturation and long-term biomass accumulation.

The compressive load exerted by a fully saturated media bed is only a fraction of the verified crushing load of Cell-Max™ Plus, making it well suited for use as a header base cover or plenum protection layer.

River Rock vs. Cell-Max™ Plus

River rock performance as a plenum layer is inherently variable due to irregular geometry, point-contact loading, and susceptibility to degradation under acidic wet/dry cycling.

In contrast, Cell-Max™ Plus distributes the load more evenly, reduces stress on air headers and laterals, and minimizes the generation of fines that can obstruct airflow.

River Rock

- Inherently variable performance

- Irregular geometry

- Point-contact loading

- Susceptibility to degradation

Cell-Max™ Plus

- Even load distribution

- Reduced stress on air headers and laterals

- Minimal generation of fines

Biological Benefit: Support of Thiobacillus Activity at the Base Layer

In addition to its mechanical and structural advantages, the use of Cell-Max™ Plus as a header base cover layer provides a meaningful biological benefit in sulfur-based odor control applications.

The lower zone of biofilters and bioscrubbers is typically characterized by higher moisture levels, elevated hydrogen sulfide concentrations, and increased availability of reduced sulfur compounds. These conditions favor the establishment and activity of autotrophic sulfur-oxidizing bacteria, particularly species of the genus Thiobacillus.

Cell-Max™ Plus offers a stable, inorganic, high-surface-area structure that supports the attachment and persistence of Thiobacillus populations in the lower portion of the bed. Unlike river rock, which provides limited effective surface area and is prone to fouling and channeling, Cell-Max™ Plus maintains consistent porosity and moisture retention characteristics conducive to sustained biological activity.

By encouraging early-stage sulfur oxidation at the base of the vessel, the Cell-Max™ Plus plenum cover layer can function as an extension of the biologically active zone rather than an inert structural layer. This promotes:

- Earlier conversion of H2S to sulfate near the air entry point

- Reduced localized H2S breakthrough into upper media layers

- More uniform biological loading across the full bed depth

- Improved long-term stability of odor removal performance

This dual-function role — structural protection combined with biological support — represents a fundamental advantage of Cell-Max™ Plus over conventional river rock plenum layers, which are purely mechanical and provide minimal biological contribution.

Reduced Freight, Installation Labor, and Equipment Requirements

A significant advantage of Cell-Max™ Plus as a plenum protection or header base cover layer is its very low bulk density, which directly reduces freight cost, installation labor, and equipment requirements compared to river rock and other rock-type media.

Cell-Max™ Plus bulk density (dry) is 10.5 lb/ft3 (168 kg/m3). By comparison, typical rock-type media commonly range from 90 to 120 lb/ft3, resulting in substantially higher shipping weights and more demanding handling requirements.

Cell-Max™ Plus is supplied in 100 cubic foot bulk super sacks, allowing for efficient truck loading, controlled placement, and installation using light forklifts or small telehandlers. This packaging approach:

- Minimizes job-site congestion,

- Reduces the need for heavy lifting equipment or conveyors, and

- Enables faster installation with smaller crews.

The combination of lightweight media and bulk super sack delivery results in lower total installed cost, particularly on retrofit and re-bed projects where access limitations and downtime duration are critical considerations.

Conclusion

With a verified crushing load of 13,000 lb/ft2 (622 kPa), reduced installed weight, and superior durability in acidic odor-control environments, Cell-Max™ Plus represents a technically sound and operationally advantageous replacement for river rock plenum cover media.

For the purposes of this white paper, the term “river rock” is used generically to represent river rock and other rock-type media including, but not limited to, gravel, lava rock, crushed stone, and coated aggregate media commonly used as plenum or header base cover layers.